Todos os Produtos

-

Máquina de moldagem por sopro de tanques ibc

-

Máquina de moldagem por sopro de tambor

-

Máquina de moldagem por sopro de reservatório de água

-

Máquina de moldagem por sopro de paletes

-

Máquina de moldagem de caiaques

-

Máquina de moldagem por sopro de barreiras de estrada

-

Máquina de moldagem por sopro flutuante

-

Máquina de moldagem personalizada

-

Molde de moldagem por sopro

-

Máquina auxiliar

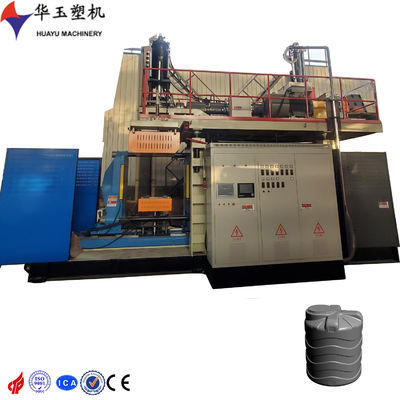

2000L 12-Layer Water Tank Blow Molder – Precision Engineered IBC Tank Blow Molding Machine for Large-Capacity Production

| Lugar de origem | China |

|---|---|

| Marca | HUAYU |

| Certificação | ISO9001 CE |

| Número do modelo | HYBM-500-2000L, 12 camadas |

| Quantidade de ordem mínima | 1 conjunto |

| Preço | 360000 USD |

| Detalhes da embalagem | ser desmontado em várias partes para transporte em contentor |

| Tempo de entrega | 4 meses |

| Termos de pagamento | T/T,L/C |

| Habilidade da fonte | 1 conjunto de 120 dias |

Contacte-me para amostras e cupons grátis.

Whatsapp:0086 18588475571

WeChat: 0086 18588475571

Skype: sales10@aixton.com

Se tiver alguma preocupação, fornecemos ajuda online 24 horas por dia.

xDetalhes do produto

| Tensão | pendente | Potência total | 648.5kw |

|---|---|---|---|

| Energia média | 320kW | Produtividade | 10-24pcs/h |

| Diâmetro do parafuso | 100 mm*7 | Relação L/D do parafuso | 28: 1 |

| Capacidade do acumulador | 60kg | Max. Tamanho do molde | 1600*2000mm ((W*H) |

| Pressão máxima do ar | 0,8Mpa | Consumo de ar | 2.3m3/min |

| Destacar | 12-Layer Co-Extrusion Water Tank Blow Molder,2000L Large-Capacity Blow Molding Machine,Precision Engineering IBC Tank Blow Molding Machine |

||

Descrição de produto

2000L 12-Layer Water Tank Blow Molder – Precision Crafted

Core Advantages

- 12-Layer Co-Extrusion Superiority: Multi-layer structure ensures exceptional barrier performance, pressure resistance and durability, ideal for long-term water storage without leakage or deformation.

- 2000L Large-Capacity Efficiency: Engineered to mold full-size 2000L water tanks in one single cycle, drastically cutting production time and boosting overall throughput.

- Precision Engineering for Consistency: High-precision control system guarantees uniform wall thickness across every layer, eliminating defects and ensuring stable product quality batch after batch.

- Industrial-Grade Reliability: Robust frame and high-quality components are built to withstand heavy-duty continuous operation, minimizing downtime and maintenance costs.

- Versatile Material Compatibility: Adaptable to a wide range of raw materials including HDPE, PP and recycled plastics, meeting diverse production needs and sustainability goals.

- User-Centric Intelligent Operation: Intuitive control interface simplifies operation and parameter adjustment, reducing the learning curve for operators and improving production efficiency.

Technical Specifications

Hydraulic System

| Main Oil Tank Capacity | 1200L | Servo motor, less energy consumption, high efficiency, low noise |

| Main Oil Pump | Gear Pump 163CC | |

| Main Oil Pump Motor | 48kW | |

| Servo Oil Tank Capacity | 200L | |

| Servo Oil Pump Model | Plunger Pump 22 | |

| Servo Oil Pump Motor | 7.5kW |

Electronic System

| Main Operation Panel | Touch Screen 12" | |

| Control System | PLC | |

| Thickness Control Points | 200 Points | |

| Temperature Control | PLC Module |

Produtos recomendados